Shock Bump Test Systems

SRS Test Systems

Centrifugal Constant Acceleration Testers

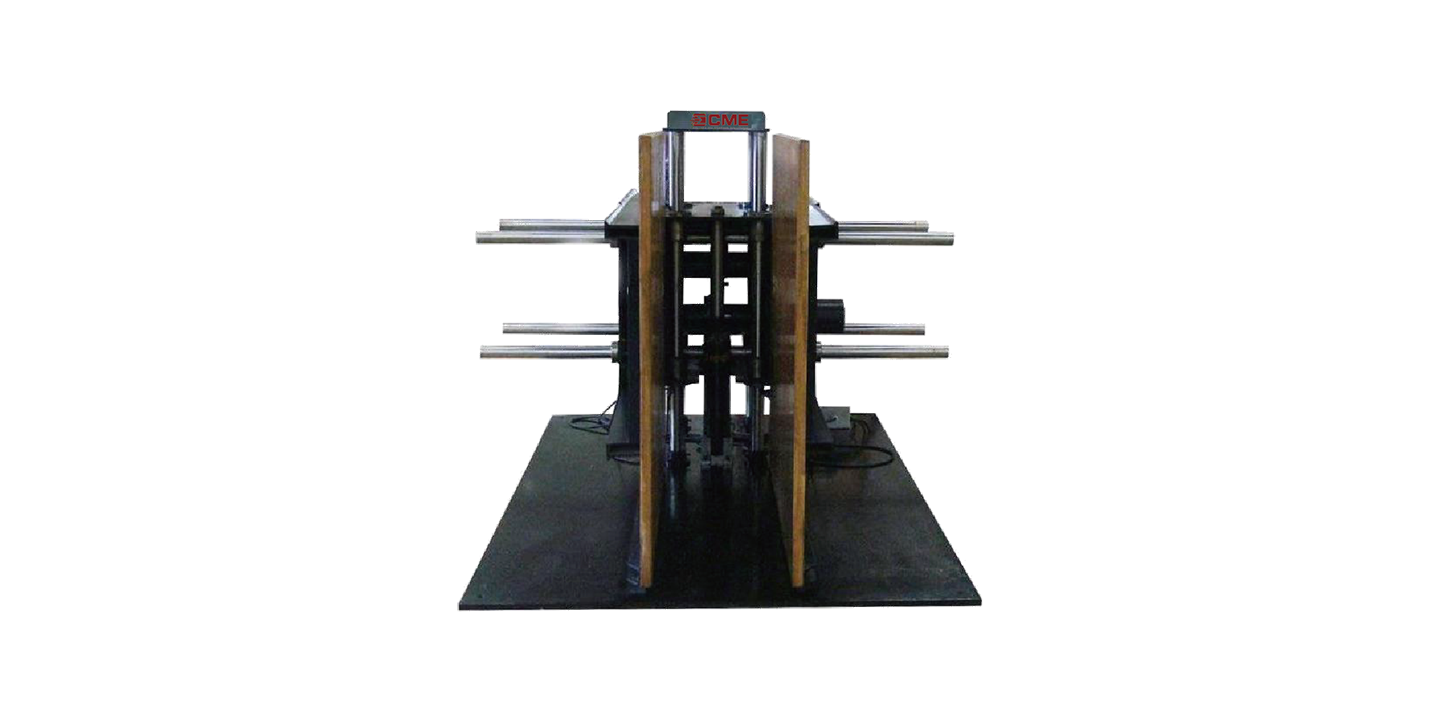

KRD32 | Non-standard Centrifugal Constant Acceleration Tester

KRD32 series non-standard centrifugal constant acceleration testing machine is test equipment for military products to simulate dynamic centrifugal motion, dual environmental force centrifugal motion and central high-speed rotating motion.